Commercial Ice Maker Repair Charlottesville VA.

Your Trusted Partner for Fast, Reliable Ice Machine Service

Why Choose VA Commercial Repair Solutions for Ice Maker Repairs in Charlottesville VA

When your business relies on a commercial ice maker, a breakdown doesn’t just disrupt operations—it puts revenue, customer satisfaction, and health compliance at risk. VA Commercial Repair Solutions delivers prompt, professional Commercial Ice Maker Repair Charlottesville VA, serving the entire Central Virginia region including Harrisonburg, Waynesboro, Staunton, Fishersville, and Lexington.

We are S.W.A.M. and eVA-certified, specializing exclusively in commercial ice maker repair—never residential units. Our experienced technicians ensure your ice machine is running efficiently, producing clean, clear, and great-tasting ice, while meeting local and FDA health standards.

- Manitowoc

- Master-Bilt

- Hoshizaki

- Beverage Air

- Ice-O-Matic

- Turbo Air

PLEASE NOTE: WE DO NOT WORK ON RESIDENTIAL ICE MAKERS or REFRIGERATORS FOR ANY REASON.

The Cost of Downtime—Why Timely Repairs Matter

- Revenue Loss: Ice shortages can halt beverage service and food prep, leading to lost sales.

- Customer Experience: Unavailable or poor-quality ice negatively affects reviews, repeat business, and reputation.

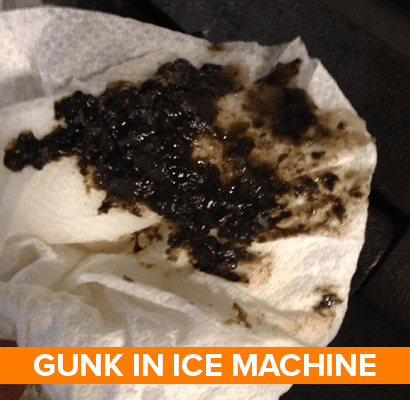

- Health Code Compliance: Dirty or malfunctioning ice makers risk violations, fines, and forced shutdowns.

- Long-Term Costs: Ignoring minor ice machine problems—like clogged filters or leaks—often results in more expensive repairs later.

Downtime affects not just your business but your bottom line. Fast, thorough repairs protect your investment and keep your operation running smoothly.

Our Proven Commercial Ice Maker Repair Process

Commercial Ice Maker Repair Process Charlottesville VA

Step 1: Rapid Response & Consultation

We prioritize emergency calls for ice machine breakdowns. Most service appointments are scheduled same-day to minimize disruption for restaurants, hospitality venues, schools, hospitals, and offices.

Step 2: Comprehensive Diagnostics

Our technicians use advanced tools to evaluate:

- Water inlet valves and filtration systems

- Evaporator plates and refrigeration circuits

- Electrical connections, sensors, and control panels

- Motors, pumps, and gear drives

- Condenser coils and ventilation systems

Step 3: Full Ice Machine Inspection & Cleaning Checklist

Every repair includes our industry-best inspection and cleaning checklist based on FDA guidance and manufacturer protocols—keeping your ice safe, clear, and compliant.

Ice Machine Inspection & Cleaning Checklist (Charlottesville VA) Interior:

- Remove all ice from bin and discard any contaminated ice

- Inspect evaporator grid and freeze pattern

- Wash all interior surfaces with food-safe cleaner

- Remove and sanitize bin drain and scoop

- Deep-clean ice bin walls, lid, and door gaskets

Water System:

- Inspect and replace water filters as needed

- Check inlet valve for leaks/clogs and clean water distribution system

- Test water pressure and system flow

Refrigeration:

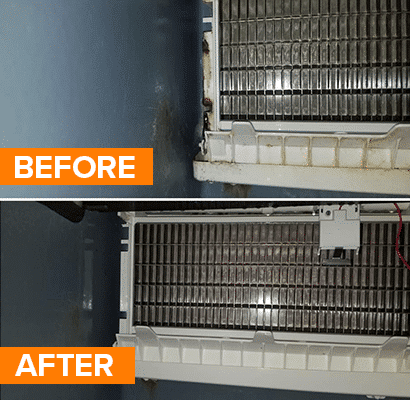

- Clean condenser coils to ensure efficient cooling

- Inspect refrigerant charge, lines, and fan motor operation

Performance Test:

- Run full ice production cycle

- Reset cube thickness control (if applicable)

- Verify ice size, clarity, and taste

- Final sanitation step with food-grade sanitizer

Documentation:

- Record all cleaning and maintenance for health department and FDA compliance

- Provide recommendations for preventative maintenance

What Sets Us Apart for Commercial Ice Maker Repair Charlottesville VA

- Brand Expertise: Our team services all leading brands—Manitowoc, Scotsman, Hoshizaki, Ice-O-Matic, and more.

- No Residential Units: 100% commercial focus ensures precise, tailored repairs.

- Parts and Labor: OEM replacement only, maintaining warranty and reliability.

- Transparent Communication: Clear explanations, up-front pricing, and written recommendations.

Common Commercial Ice Maker Issues We Resolve

- No ice production or slow cycles

- Cloudy, metallic-tasting, or smelly ice

- Water leaks or drainage problems

- Electrical faults or sensor failures

- Freezing over or temperature inconsistencies

- Unusual sounds or vibrations

Our experience means we don’t just fix symptoms—we address root causes to extend your machine’s life.

Preventive Maintenance—Protect Your Investment

Commercial Ice Maker Repair Charlottesville VA should be paired with a Commercial Ice Maker regular maintenance plan:

- Clean and sanitize 2–4 times per year

- Replace water filters every 3–6 months

- Keep condenser coils dust-free and unobstructed

- Train staff on proper use (no hands in ice bin, always use sanitized scoop)

These best practices minimize costly emergencies and help pass health inspections.

Our Charlottesville VA Service Area

We serve commercial clients in Charlottesville, Harrisonburg, Waynesboro, Staunton, Fishersville, Lexington, and surrounding Central Virginia communities.

Ready for Fast, Professional Ice Maker Repair?

Contact VA Commercial Repair Solutions—Charlottesville VA’s trusted commercial ice machine experts.

Call today for 24/7 emergency service, preventive repairs, and a full FDA-compliant inspection and cleaning checklist at every visit.